CURRENT METER CALIBRATION FACILITY AT CWPRS, PUNE

|

|

|

|

|

|

| MAJOR COMPONENTS

- Rating tank 228 m long, 3.66 m wide and 2.13 m deep

- Electrically driven rating trolley (carriage)

|

SALIENT FEATURES OF RATING TROLLEY

- Speed range 0.01 m/s to 6.0 m/s.

- AC servo motors and drives with PLC for precise speed control.

- PC based data acquisition and processing system using specially developed software.

- Conforms to National/International Standards (IS 13371-2014/ ISO 3455-2007).

|

|

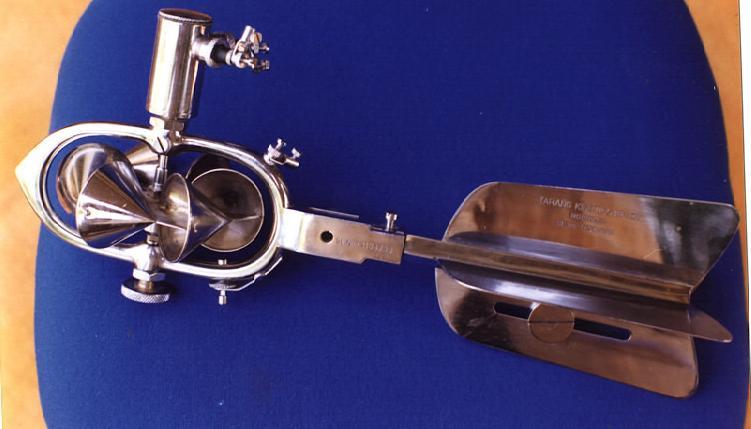

CAPABILITIES

- Servicing and repairs of old current meters.

- Calibration of conventional rotating element type current meters conforming to IS 13371-2014/ ISO 3455-2007.

- Calibration of sophisticated stationary element type electromagnetic and acoustic current meters used in oceanography.

|

| METHODOLOGY |

|

|

Calibration of current meters in straight open tank (rating tank) is an internationally accepted practice. A new current mete is required to be calibrated so as to establish relationship between its rotational speed and the velocity of flow. Even for old current meter periodical calibration is necessary to account for possible wear and tear of its certain parts. As per IS 13371-2014 it is mandatory to recalibrate the current meters at yearly interval or after 300 hrs of use whichever is earlier.

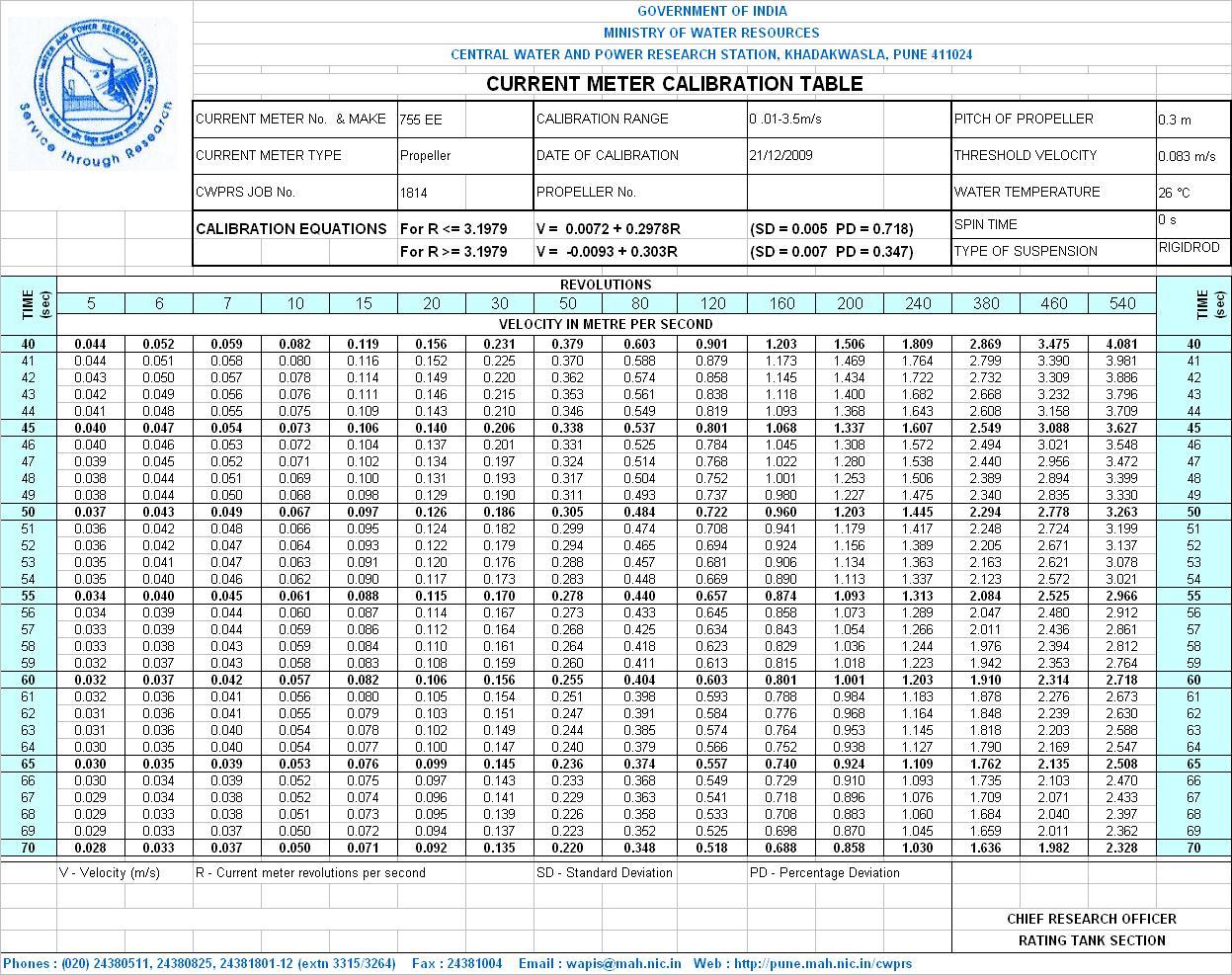

During calibration, the current meters are suspended from the carriage and drawn through still water containing in the tank at a number of steady speeds of the trolley. Simultaneous measurements of the speed of the trolley and the rate of revolution of rotor of the current meter are made. The two sets of values are related by one or more equations. The calibration of each current meter is provided in the form of Calibration Table suitable to gauging technique in use.

|

|

| CLIENTELE

- Central Water Commission

- Central and State Government Departments/undertakings

- Railways/ Private Agencies/current meter manufacturers

|

|